Between 15,000 and 20,000 domestic hot-water pumps are installed in Denmark. Recent years' developments in the Danish power industry have caused sales of domestic hot-water pumps to stagnate at about 600 annually. Most domestic hot-water pumps manufactured in Denmark are exported to countries outside the EU. In Denmark, total production of domestic hot-water pumps today runs at about 3,000 units. The number of domestic hot-water pumps manufactured in Denmark is expected to reach about 5,000 annually in 2002.

The overall objective of the project is to promote the use of CO2 as a replacement for the potent greenhouse gasses - called HFCs - in domestic water pumps at cooling and heating pump plants. This is necessary to reduce emissions of potential greenhouse gasses.

Especially in plants mounted indoors as domestic hot-water pumps, CO2 as a refrigerant represents an excellent replacement for the previously used refrigerants HCFC and HFC. The project will set up general system requirements for plants having CO2 as refrigerants, and will primarily focus on heating pumps for domestic water. The system requirements set up in the project can also be applied to similar plants used for refrigeration.

The overall project was split into two main phases. The first one established performance requirements for cooling and heating pump plants applying CO2 as refrigerant, and studied the components. A control strategy was reviewed. Finally, the results were reported, and the knowledge gained was disseminated. The second main phase is presently being realised. Its objective is to set up and test prototypes, and it is expected to conclude in mid-2002.

CO2 represents an interesting alternative to HFC refrigerants, especially in domestic hot-water pumps. Today, the range of commercially available components able to use CO2 as refrigerant is limited. This makes it difficult for manufacturers to realise conventional product development. But the range of compressors and valves for CO2 is expected to increase considerably in the near future (two to five years). Until then, a significant share of the development work in the area will be centred on universities and institutes. But the refrigeration and heating pump industry is already recommending that actual product development for CO2 plants be launched.

The data included in the report enables the industry to contact suppliers of CO2 components, with a view to establishing actual cooperation. The report estimates that such contacts will expedite the development of CO2 components. In general, manufacturers do not develop or market components before their customers start asking for them. And this is where the industry plays an important role.

|

|

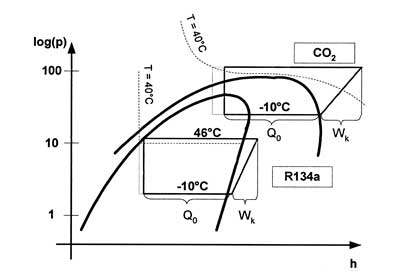

Figure 1:

Circuit processes for R134a and CO2.

The project opened by describing the requirements posed to plants containing CO2 and the general requirements posed to domestic hot-water pumps. When CO2 is used as refrigerant, system pressure should be the focus of attention. For example, pressure in the evaporator reaches close to 70 bars. Figure 1 shows the circuit process for CO2 and the conventional refrigerant R134a, set into a log p,h chart (pressure, enthalpy chart).

The project set up a static simulation program aimed at studying the advantages gained from using CO2 as refrigerant instead of R134a. The simulation program makes it possible to compare the energy efficiency of a heat pump containing CO2 and one containing R134a. Comparisons plainly show that CO2 is an excellent alternative to HFCs in hot-water pumps, especially when it comes to domestic hot-water pumps able to utilise the wide temperature fluctuations in the gas cooler. At an exterior air temperature of 2°C and an inlet temperature in the water from the heat pump of 65°C, the coefficient of performance (COP) of the refrigerating system was found to improve by about 48% in a pump using CO2 compared to R134a.

The gain is significantly lower in heat pumps used solely for room heating, but CO2 is still considered an interesting alternative to HFC refrigerants. When the outside air temperature is 2°C and inlet temperature in the water from the heat pump is 35°C, calculations show a drop in the refrigerating system's coefficient of performance (COP) of about 12% when CO2 is compared to R134a. If the inlet water temperature is changed to 55°C, calculations show that CO2 will achieve an improvement in the refrigerating system's coefficient of performance (COP) of about 27% compared to R134a. The latter operational state is interesting with respect to room heating, as the system runs under such conditions for many operational hours in the heating season.

The survey of components suited for CO2 included results from a conference on natural refrigerants held in July 2000 (4th IIR-Gustav Lorentzen Conference on Natural Working Fluids at the Purdue University, Indiana, USA). At the conference, a range of projects currently being conducted internationally were presented. The survey chiefly focused on the status of compressors for CO2. The survey shows that several compressors exist that can be used for airconditioning in automobiles and small airconditioning and heat pump plants. As for the major plants, many suitable compressors are available today. However, common for all compressors is that they are still at the prototype stage, and only a few compressors - all for subcritical operation - are marketed commercially.

Like the compressors, valves (high-pressure and expansion valves) for CO2 are still at the prototype stage. Users can make heat exchangers (evaporators and gas coolers/condensers) for CO2 or obtain them on the market, though the supply is relatively limited. However, co-axial exchangers can be used as gas coolers for domestic hot-water pumps, and conventional components (fins mounted on pipes) can be used as evaporators.

The project also reviews the other components for domestic hot-water pumps containing CO2. A range of hot-water tanks was reviewed, and the report describes how they should be designed to utilise the properties of CO2 optimally.

The properties of CO2 make it possible to adjust plants differently from conventional refrigerating plants. For instance, pressures and temperatures in the gas coolers can be controlled individually. This is a useful option, if the possibility of comprehensive adjustment of the plant capacity is required (presupposes that a transcritical fluid is present in the gas cooler). The facility would make it possible to avoid conventional capacity-adjusting methods, such as hot gas or bypass. However, it would still be advantageous to control capacity by controlling the compressor revolutions/minute (frequency adjustment/demand control).

A range of concepts was reviewed, aimed at describing possible system set-ups for a domestic hot-water pump containing CO2. All concepts are applicable in practise, but which concept is relevant in the actual situation depends on several aspects, for instance production methods, supplier relations and whether the systems should be prepared for more application fields.

In connection with the Danish EPA’s action plan for phasing out industrial greenhouse gasses, including HFC refrigerants, the refrigeration and heat pump industry is presently seeking alternatives to the refrigerants currently in use. One of the refrigerants expected to be able to replace the HFCs is CO2 (R744). Calculations show that using CO2 as opposed to the traditional refrigerant R134a in heat pumps for domestic hot water heating improves efficiency by up to approx. 50 percent. At the same time, the GWP (global warming potential) of R134a is approx. 1,300 times greater than that of CO2. The project report is a technical account primarily directed at technical personnel in the refrigeration and heat pump industry.